Problem Statement

Build a manually controlled robot capable of traversing a broken pipe and repairing it on the way, in this case, popping corks plugged in the pipe. For more details on the event refer to our website.

Required Material

| Material | Quantity |

| Wheels | 3 |

| 30 rpm DC motor | 1 |

| 100 rpm DC motor | 4 |

| Castor Wheels | 3 |

| Rack & Pinion | 1 |

| Three way switches | 3 |

In this DIY , we have divided the design of the robot into 4 parts:

- Body

- Traversal Mechanism

- Arm and Popping Mechanism

- Control box

Body

The body of the robot is designed in such a way, that it can traverse the central rod of the arena. You may also try other body designs which use the outer pipe or a combination of the rod and pipe to travel.

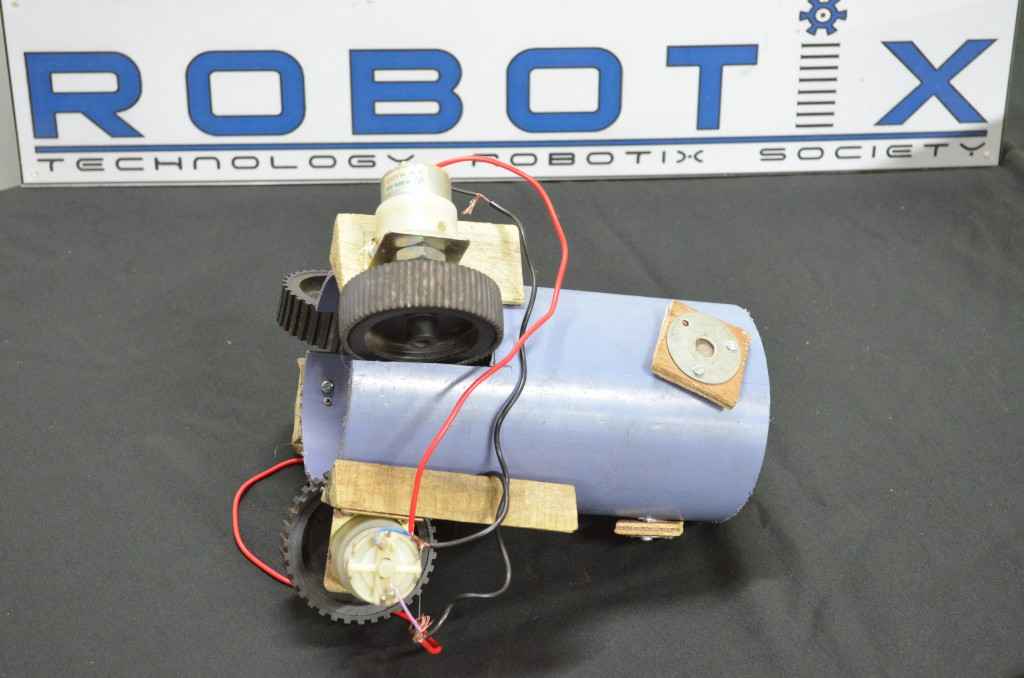

Traversal Mechanism

You need to decide here, as to what mechanism you are going to use to traverse the arena. The mechanism must be sturdy, it must be able to grip the pipe, and obviously, it must be able to move forward and backward. 3 wheels are placed at angles of 120 degrees from each other around the body to drive the robot forward and backward.

3 Castor wheels at the other end of the robot provide support during pipe traversal.

The completed Traversal Mechanism.

Arm and Popping Mechanism

The C-shaped rotatory mechanism allows the attached popping mechanism to rotate around the robot.

The popping mechanism consists of a rack and pinion system. The rack also acts as part of the arm and can be pushed to the right and left by the pinion.

When attached as shown, that is tangential to the end of the C rotatory mechanism, the popping mechanism allows the mechanism to get a 360 degree reach around the robot.

#

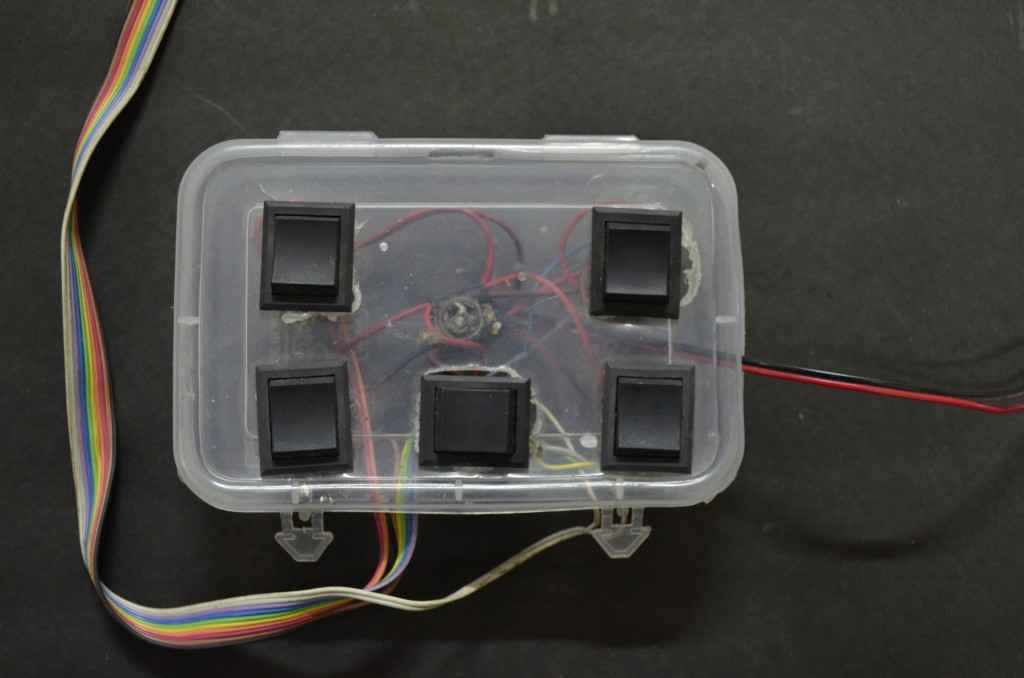

Control Box

As we are using 5 motors we need 5 three way switches.

The control box used in this robot

Completed robot

| Body, traversal, and arm come together in one entity to take on the challenge: **InspiralOn | Robotix 2014**. |

Refer to the video tutorial for more details. You can also view the DIY in a pictorial and step-by-step manner here.